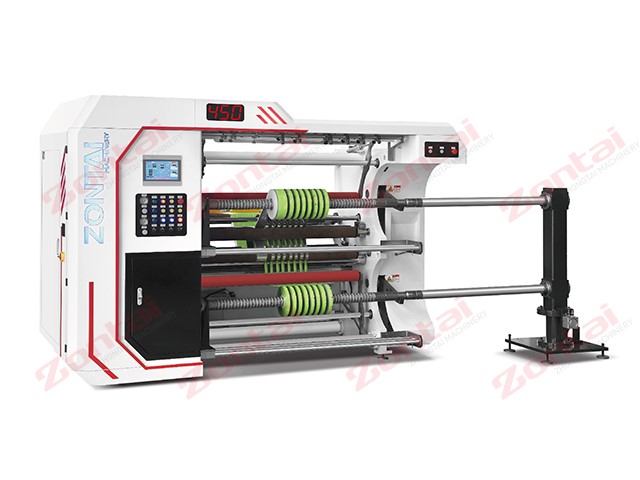

The machine applies to cellophane, PET, OPP, CPP,PE, PS, PVC and computer security labels, electronic computers, optical materials, film roll, foil roll, laminated rolls, all kinds of paper rolls, film and printing of various materials to slitting.

Features:

1, Unwinding unit: Shaftless auto loader;

LPC for tracking both edge and printing marks,

Unwinding tension through magnetic brake and loadcell for close-loop auto tension.

2, Slitting Unit: 10 sets of razor knives

3, Rewinder shaft: 3inch friction shafts.

4, Rewind tension: proportional valves controlled.

5, Rewinder pressure unit: pressure rubber roller controlled by air cylinder

6, Waste edge processing section: blowing fan included.

7, Electrostatic elimination Unit: install in up and down rewinder part

8, Finished Produce unloading Unit: discharge rack

9, PLC control system: Siemens PLC and touch screen.

Main technical parameter:

|

Jumbo roll width |

1000mm |

1300mm |

|

Diameter of roll |

800mm |

800mm |

|

Diameter of rewinding |

600mm |

600mm |

|

Inner dia.of paper core |

3''(6'') |

3''(6'') |

|

Slitting speed |

10-400m/min |

10-400 m/min |

|

Tolerance of EPC |

+-0.1mm |

+-0.1mm |

|

Min.width of produce |

50mm (30mm) |

50mm (30mm) |

|

Total power |

12KW |

12KW |

|

Weight |

3800Kg |

4000kg |

|

overall dimension(LxWxH) |

2.2mx4mx2.1m |

2.2mx4.3mx2.1m |

Optional device:

1, 6inch rings for rewinder shaft

2, auto push device for rewinder rolls

3, trimming edge rewinder machine